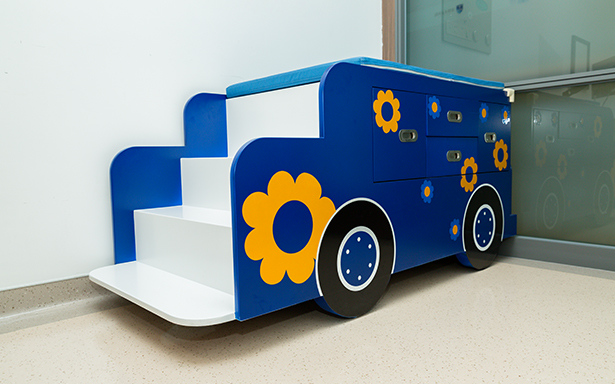

Artificial boards have now become the main surface decoration and structural materials for medical furniture. They are made of wood or other non-wood plant fibers, separated into various unit materials through certain mechanical or chemical processing, and then made into boards after applying or not applying adhesives and heating and pressurizing. Wood artificial boards mainly include the following categories.

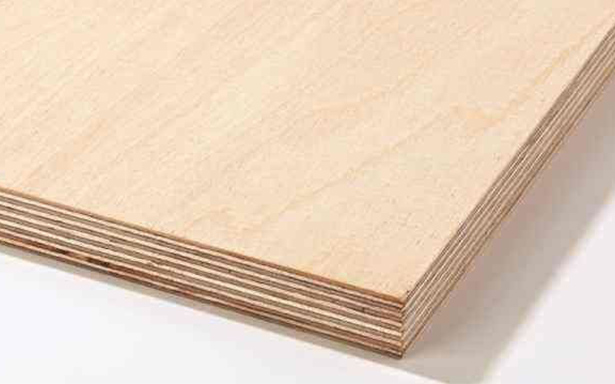

1. Plywood

Plywood is a three-layer or multi-layer board material made by peeling logs into veneers or planing wood into veneers, and then gluing them together with adhesive.

There are many ways to grade plywood. In view of the functional characteristics of medical furniture, when purchasing medical furniture, you should choose plywood of Class III or above, and try to choose Class II plywood.

2. Particleboard

Particleboard is also called particle board, particle board, and bagasse board. It is a man-made board made of wood or other lignocellulosic materials. After applying adhesive, the artificial board glued together under heat and pressure is also called particleboard.

Particleboard has the advantages of uniform structure, flat surface, homogeneous length and width, no growth defects, and large format. It can be processed into large-format boards as needed. It is a good raw material for making furniture of different specifications and styles. The finished particleboard does not need to be dried again and can be used directly, so it has good sound absorption and sound insulation properties.

In addition to the above advantages, it also has the disadvantages of large release of free formaldehyde, low plane tensile strength, rough edges, and easy moisture absorption.

3. Fiberboard

Fiberboard, also known as density board, is a man-made board made of wood fiber or other plant fiber as raw materials, with urea-formaldehyde resin or other suitable adhesives added. Fiberboard has the advantages of uniform material, small vertical and horizontal strength difference, and not easy to crack, and has a wide range of uses.

According to density, it is divided into soft fiberboard, medium density fiberboard and high density fiberboard. Medium density fiberboard (hereinafter referred to as MDF) is generally used as the material for making furniture. Its various properties are better than particleboard, especially easy cutting and strong board edges. It is a good material for making medium and high-end furniture and interior decoration, but its price is higher than particleboard.

Plywood, particleboard and medium-density fiberboard are commonly known as the "three boards" in the furniture manufacturing and decoration industries.

4. Hollow slab

Hollow board is a hollow composite structural board composed of a lightweight core material (hollow core board) and a cladding material. The core material of the hollow board used in furniture is mostly composed of a surrounding wooden frame and hollow filler, and then one or both sides are covered with plywood, fiberboard or decorative board, which is called a cladding board.

Hollow boards have the characteristics of light weight, small deformation, stable size, flat board surface, beautiful material packaging, etc., and have certain strength. They are good lightweight board materials for furniture production and interior decoration. The peripheral frame of the hollow board used for furniture can be made of wood or various wood-based panels, and the core material can be made of wood strips or wood-based panels in strips, grids, lattices, meshes, etc., or filled with paper honeycomb materials.

If medical furniture has higher moisture-proof requirements, wood or wood-based panel core materials should be used as much as possible.

5. Blockboard

Blockboard is commonly known as core board, which is made of two pieces of veneer with the same thickness and parallel wood strips glued together. Compared with "three-board", its characteristics are closest to natural wood, while overcoming some shortcomings of wood, so it is more in line with human needs.

Blockboard is similar to plywood and also has a variety of grading methods. For medical furniture, in addition to its formaldehyde content reaching the E1 standard or above, medical furniture must be made of Class II blockboard to meet the moisture-proof and antibacterial functions.

In short, when purchasing medical furniture, in addition to considering the cost budget, it is also necessary to comprehensively consider factors such as usage function, usage scenario and environmental space. Dain Medical has many hospital furniture project cases, and its rich medical furniture cases and high-quality services are deeply recognized by customers.

400-9600-778

400-9600-778